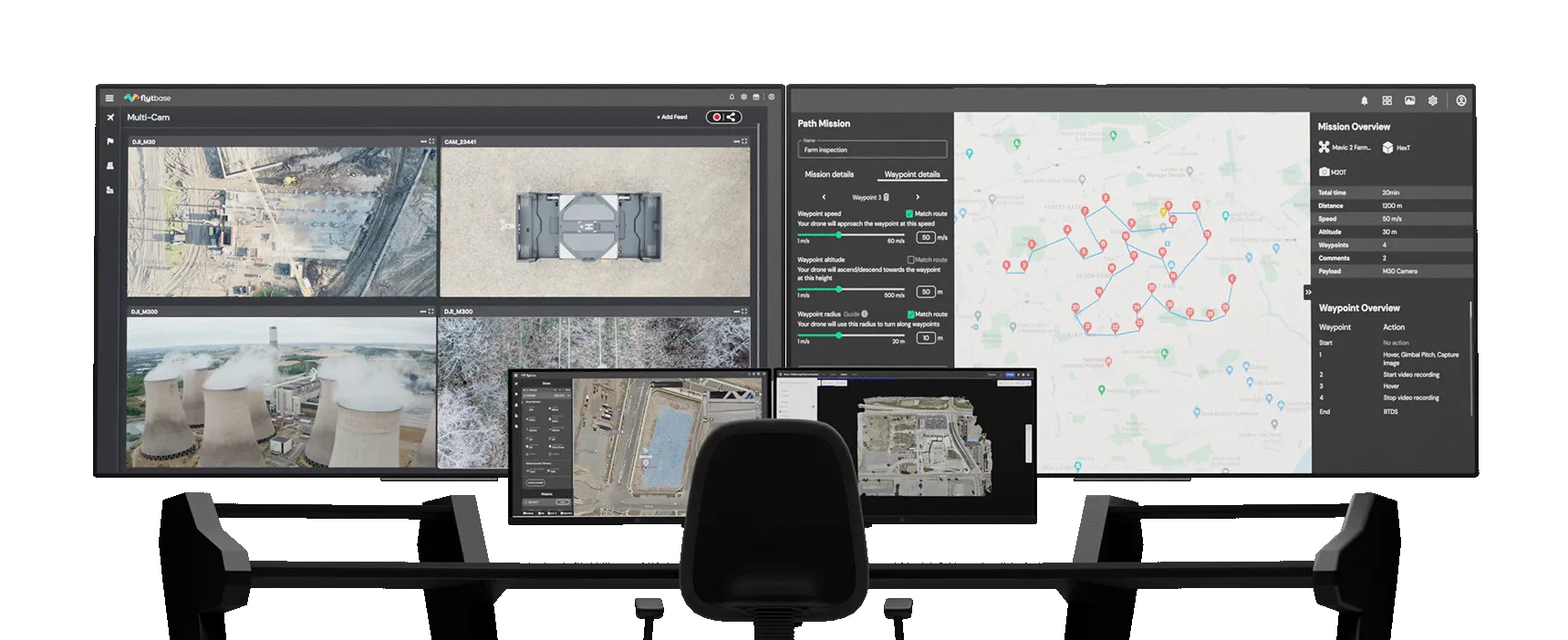

Drone Autonomy Software Platform Designed For System Integrators

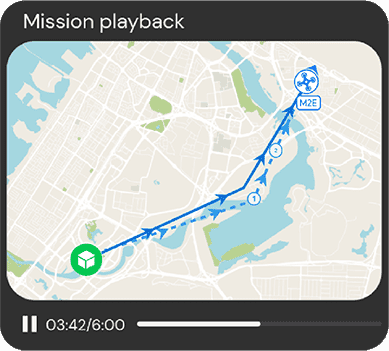

Automate your repeatable and routine drone operations with drone docks — for site security, asset inspection, or emergency response — from wherever you are.

.png)

.png)

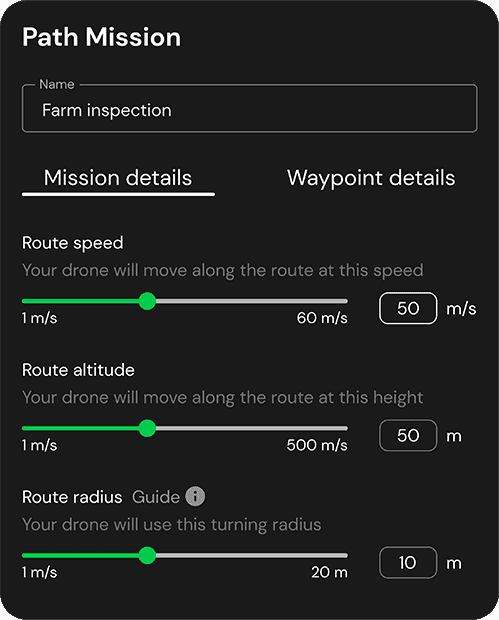

FlytBase's enterprise-grade secure, reliable & scalable platform is designed for system integrators to seamlessly mix & match various components of the drone ecosystem, including hardware, BVLOS capabilities, and data analytics/management apps to fully automate custom workflows for enterprise use-cases like security, inspections, or emergency response.

Drone & dock fleet management, from a unified command center software.

Here's why remote drone operators love FlytBase.

Architected to be Hardware-Agnostic

Combine any drone, docking station, payload, accessory & sensor of your choice. FlytBase supports it all.

Learn More

.png)

One Platform. Multiple Applications.

We wanted to optimize inspection routes at the Genelba power plant since the area was too large for inspectors to cover in a single shift. We decided to employ the FlytBase-powered autonomous drone-in-a-box solution due to its superior unattended flight technology and affordable price.

.png)

.png)

We're invested in your success

From seamless implementation support to real-time troubleshooting, we're committed to helping you scale, and optimize your drone operations.

Contact Us

Onboarding and training support

Priority email, chat and phone support

Technical consulting

3.214910

103.314485

51.52104986638123

-0.10886444486544199

43.53353348648237

-79.67242417851017

-3.497686

126.684881

45.047818

0.785082

37.906411

128.451058

31.0461

34.8516

26.171468

-104.340543

36.085003617012504

-94.15461766622452

-39.751749

-62.401771

16.724757

-98.599794

-48.174970

-75.070513

25.7617

-80.1918

52.314616

-115.506654

16.565393

101.370801

27.064139

142.225443

26.136528

127.689675

-3.056855

106.637336

42.991668

6.206646

23.8859

45.0792

29.327650

13.281277

27.978930

-5.632287

7.9465

1.0232

33.942791

-118.410042

Partner network that extends globally

Tap into our customer base, expand your network and market your services to a larger audience in the dynamic world of aerial operations with FlytBase.

Locate a partner

146

Drone Solution Providers

18

Docking Station OEMS

Customer love that spans worldwide

Hear what drone operators have to say about FlytBase

“FlytBase's drone video feed over 4G/LTE helps SBB teams quickly monitor railway infrastructure and make informed decisions during emergencies. This improves operational efficiency."

“It is a pleasure to work with the FlytBase team to solve problems and create the most efficient product. We are excited to shape the future of the ‘Internet of Drones’ together!”

"FlytBase's UI is intuitive and user-friendly, with high-level software and customization options. It adds value to BVLOS operations for any application."

“Flyt APIs helped NatureEye quickly develop their product with live-video streaming, telemetry, and fleet control. Safety and security features ensure reliable operations. "

-2.png)

"FlytNow outperformed our expectations with its intuitive UI, seamless integration with DIAB solutions, and quick support. It worked smoothly with both DJI and open-source drones such as Ardupilot/PX4."

“FlytBase's drone video feed over 4G/LTE helps SBB teams quickly monitor railway infrastructure and make informed decisions during emergencies. This improves operational efficiency."

“It is a pleasure to work with the FlytBase team to solve problems and create the most efficient product. We are excited to shape the future of the ‘Internet of Drones’ together!”

"FlytBase's UI is intuitive and user-friendly, with high-level software and customization options. It adds value to BVLOS operations for any application."

“Flyt APIs helped NatureEye quickly develop their product with live-video streaming, telemetry, and fleet control. Safety and security features ensure reliable operations. "

-2.png)

"FlytNow outperformed our expectations with its intuitive UI, seamless integration with DIAB solutions, and quick support. It worked smoothly with both DJI and open-source drones such as Ardupilot/PX4."

"FlytBase has helped us provide an easy to use interface for our customers to interact with their DiaB solution."

"FlytBase helps us enable autonomous applications like perimeter surveillance, emergency response inspections, control operations, and much more."

“Our collaboration with FlytBase enables us to offer a fully autonomous system. Their pace of development in new software features allows us to quickly adapt to client’s needs.”

"FlytBase enables us to assure civilian safety by preventing/looking for local fires in Korea's challenging terrain."

"FlytBase has the optimal solution for our demanding drone-in-a-box requirements, providing our customers an easy Human Machine Interface (HMI), for fast and secure deployment of the drones."

"FlytBase has helped us provide an easy to use interface for our customers to interact with their DiaB solution."

"FlytBase helps us enable autonomous applications like perimeter surveillance, emergency response inspections, control operations, and much more."

“Our collaboration with FlytBase enables us to offer a fully autonomous system. Their pace of development in new software features allows us to quickly adapt to client’s needs.”

"FlytBase enables us to assure civilian safety by preventing/looking for local fires in Korea's challenging terrain."

"FlytBase has the optimal solution for our demanding drone-in-a-box requirements, providing our customers an easy Human Machine Interface (HMI), for fast and secure deployment of the drones."

.svg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)

.png)

.png)

.jpg)